Usage Areas of Composite Plywood

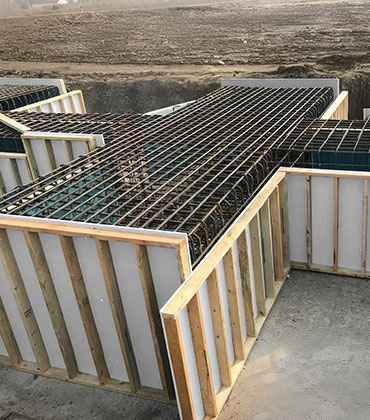

Construction

Composite Plywood is widely used in construction for its strength, lightness, and resistance to environmental factors. Being made from natural bor minerals and not derived from petroleum, it provides healthier indoor air quality and supports sustainable building certifications. Its recyclability helps reduce construction waste and its long service life lowers costs over time.

Furniture

In the furniture sector, Composite Plywood is valued for its durability and design flexibility. Its non-toxic, formaldehyde-free structure ensures healthier living spaces, while the natural bor content increases resistance to moisture and bacteria. The recyclability of the panels supports environmentally conscious manufacturing.

Commercial Vehicles

Composite Plywood is a preferred material for commercial vehicle interiors and floors due to its lightness and robust structure. Since it is not petroleum-based, it does not emit harmful VOCs, making vehicle interiors safer and more comfortable. Its resistance to wear and easy recyclability make it a sustainable option for fleet owners.

Marine Vehicles

The natural bor-based composition offers excellent resistance to water and humidity, making Composite Plywood ideal for use in marine vehicles. It does not rot or deteriorate like traditional wood, and its recyclability makes it a more sustainable alternative in marine environments.

Packaging

For packaging, especially for food and sensitive goods, Composite Plywood stands out as a safe and hygienic solution. Its lack of petroleum derivatives ensures there is no harmful residue, and its bor content inhibits bacterial growth. After use, the material can be recycled, reducing packaging waste.

Special Productions

In custom manufacturing and special projects, Composite Plywood’s processability and ability to take on different forms make it highly adaptable. The use of natural and recyclable raw materials ensures that even bespoke solutions remain environmentally friendly.

Container

Composite Plywood is favored in container production for its strength, weather resistance, and long-term stability. Its petroleum-free composition means less environmental impact, while its bor content protects against mold and pests.

Parquet

As a parquet subfloor or even for visible surfaces, Composite Plywood delivers dimensional stability and moisture resistance. No petroleum-based chemicals means healthier indoor air, and full recyclability supports green building standards.

Machinery and Industry

Used in machinery bases and industrial flooring, Composite Plywood’s high load capacity and durability stand out. Bor-based, non-petroleum composition offers safety advantages in sensitive industrial environments, and after service life, it is easily recyclable.

OSB Alternative

As an alternative to OSB, Composite Plywood offers higher moisture resistance and a more uniform, stable structure. The absence of petroleum-based adhesives and the use of bor minerals provide both health and fire safety benefits, as well as ease of recycling.

Garden Furniture

In outdoor furniture, Composite Plywood’s bor-enriched structure protects against rot, insects, and weathering. Unlike conventional materials, it contains no petroleum by-products, so it does not release harmful substances into the garden environment. Its recyclability also makes it a sustainable choice for eco-conscious consumers.

Door Panels

For doors, Composite Plywood combines strength and lightness, making installation and operation easier. Its non-petroleum composition improves indoor air quality, while bor content enhances resistance to moisture and deformation. At the end of its life, it is fully recyclable.

Wall Decor Panel

As a decorative wall panel, Composite Plywood offers design flexibility and a hygienic, low-emission surface. Its natural ingredients, including bor minerals, contribute to a healthy interior environment and long-lasting aesthetic appeal. Panels can be recycled after use.

Elevator Interior Coating

In elevator cabins, Composite Plywood provides both fire resistance and a luxurious appearance. Its petroleum-free composition eliminates harmful emissions in closed spaces, while bor content helps prevent bacterial growth. Recyclability further increases its appeal for green building projects.

Exterior Wall Coverings

Composite Plywood is ideal for exterior cladding thanks to its weather, UV and moisture resistance. It does not contain petroleum-based chemicals, so it is safe for the environment, and its bor-based formula ensures long-term performance. At the end of its use, it can be fully recycled.

Caravan

Caravans benefit from Composite Plywood’s light weight, durability and resistance to humidity. The lack of petroleum content means healthier air and a reduced risk of odors inside the vehicle, while recyclability supports eco-friendly travel lifestyles.